How to repair timber Bressumer Beams

This project is presented by Property Repair Systems. We show you how to make Structural repairs to Bressumer beams inside buildings without destroying sound timber.

Definition of a Bressumer Beam

"a spanning beam forming the direct support of a wall or timber framing above it." (Definitions may vary regionally, as may the spelling)

Bressumers are similar to Lintols, but generally much larger and often installed as pairs.

Typical Shop Front Bressumer

Common Location in Buildings

Shop Fronts - spanning across the front windows and doorway

Decay causes

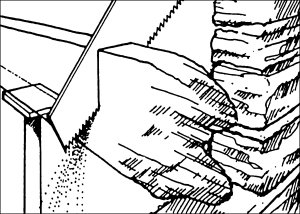

Shop Fronts - blocked or damaged gutters and downpipes.

Wet rot and insect attack then destroy the bearing ends.

Wet rot on a Bressumer Beam end

Insect damage in a Bressumer Beam end

Other Factors often seen on Survey

Party Wall - terraced shops, sharing guttering and downpipes

Cast iron downpipes crack and corrode

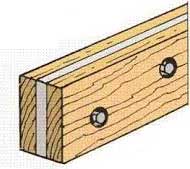

Multiple beams - often found in pairs or triples, one behind another, occasionally with a steel flitch plate in place

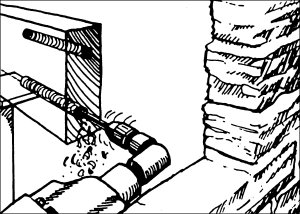

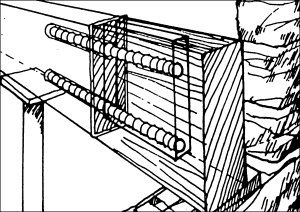

Inserting a TRS repair piece from beneath a triple Bressumer Beam.

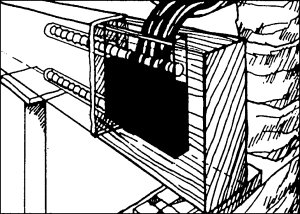

Flitched beam showing a metal plate bolted between two timber faces.

Information required from Survey of a Bressumer Beam

Access for Repair - usually from the outside or top, but may be considered from the inside or from beneath (hardest physically for the Technician).Note - check the two neighboring properties for similar decay. Compression during rotting often causes cracking to external render. Look for similar cracks around windows - lintols may also be decayed.

Size - width, depth, length, bearing support length

Number - one, two or three - may vary in size

Timber type - softwood (Pine) or hardwood (Oak), not known

Decay type - wet rot, insect attack (CFB, DWB or Longhorn), Dry rot

Amount to cut off - drill test holes if possible, or tap with a hammer

Final appearance required - visible but painted, decorative natural finish, hidden

Handed - a sketch is useful, with dimensions

Repair Options for Bressumer Beams

Repair Types - solid resin or Timber Resin Splice (TRS)

Most popular access Types - top slot, side slot, bottom slot

TRS Types - Top Slot = Type C, Side Slot = Type D, Bottom Slot = Inverted Type C

Special situation - multiple Bressumers - if repaired entirely from the front or the rear face extra timber has to be removed from the outer timber to give access to the slot cutting face in the inner parent timber.

Photo Gallery for Bressumer Repairs by TRS Type

Type A - Solid Epoxy Resin - removable shuttering - drilling up the end grain of the Parent timber on Site

Type B - Solid Epoxy Resin - permanent shuttering - drilling up the end grain of the Parent Timber on Site

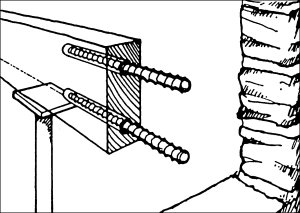

Type C - Timber Resin Splice supplied with fitted bars - Top Slot(s) in the Parent timber.

Type D - Timber Resin Splice supplied with fitted bars - Side Slot(s) in the Parent timber

Type E - Timber Resin Splice supplied with Top Slot(s) - drill holes up the end grain of the Parent timber.

Type F - Timber Resin Splice supplied with Side Slot(s) - drill holes up the end grain of the Parent timber.

Type G - Timber Resin Splice supplied with Top Slot(s) - cut Top Slot(s) in the Parent timber.

Type H - Timber Resin Splice supplied with Side Slot(s) - cut Side Slot(s) in the Parent timber.

Heritage Considerations for repairing Bressumer Beams

Repair Type - a Conservation Officer will generally prefer a Timber Resin Splice over a Solid Resin Repair

Structural Epoxy Pouring Grout - solid resin. Timber Resin Splice (TRS) in Southern Yellow Pine.

TRS Type - a Conservation Officer will generally prefer least damage to the parent timber, so TRS Types E (Top Slot) and F (Side Slot) may be offered, in which the slots are created during Manufacture in the new timber and the Technician drills holes up the end grain of the Parent. This is only feasible if the cut off length is at least 600mm.

TRS Type E Steps - Technician has to drill up the end grain, so needs good clearance to the wall.

More unusual Timber Resin Repair types

Mouldings - sometimes found on the visible decorative faces or edges of Bressumers

Curved Beams - mainly arches and corbels, can be found under Bressumers

Glulams - can be used as Bressumers

Dug outs - where the outer faces of a Bressumer can be saved as a 'shell' into which bars and resin can be placed, to create a hidden repair or strength upgrade.

Structural Calculations for Repairing Bressumer Beams

Free of charge - our Design and a Check Calculation - not Insurance Indemnified - we are not Structural Engineers - same day service

Chargeable - independent Structural Engineer - ask for one of our Forms - Indemnified by a Qualified Structural Engineer - allow at least 5 working days.

Bressumer Structural Data Collection Form - click here for the Form used when we submit your Beam Repair to a Structural engineer.

Epoxy Resins for Repairing Bressumer Beams

To buy resins - visit our Resins Shop

Sealing beam end face to a TRS or to seal Shutter Boxes - Quick Setting Wood Filler

Pouring into Shutter Boxes (Type A or Type B) and Top Slots (Type C, E) - Structural Epoxy Pouring Grout

Injecting into Side Slots (Type D and Type F) - Structural Epoxy Pouring Grout plus 1 litre Cartridges and Skeleton Gun

Bonding Bars into timbers on site - for Solid Resin Repairs, Type A and Type B and TRS Timber Kits Type E and Type F - Thixotropic Epoxy Injection Resin plus 400cc Cartridge Kits and Skeleton Gun, with extension tubes for the Cartridges.

Bars used for Repairing Bressumer Beams

Bars fitted to TRS Units - Zinc Plated High Tensile Grade 8.8 Steel Allthread

Couplers - available for joining threaded bars in some applications

Bars fitted on Site - either Zinc Plated High Tensile Grade 8.8 Steel Allthread or Epoxy-Glass Bar

Types of Wood used for Timber Resin Splice Bressumer Repair Kits

Standard Kiln Dried Softwood (Pine) - white or Redwood Pines, Strength Graded C24

Non standard Kiln Dried Softwood (Southern Yellow Pine, Douglas Fir) - yellow or red striped Pines, Strength Graded C24

Non standard Kiln Dried Hardwood (Oak) - English or American Oaks, not Strength Graded

Non standard Air Dried Hardwood (Oak) - English Oak, will contain insect holes, shakes and splits, will not be dimensionally stable, may shrink, twist and split further in service.

Special Tools for Repairing Bressumer Beams - we hire these tools

Cutting Slots - Low Speed, High Torque , reversible electric drilling machine (minimum power - 1000 watts), in conjunction with fully fluted wood Augers

Drilling Holes up the ends of beams - Low Speed, High Torque , reversible electric drilling machine (minimum power - 1000 watts), in conjunction with fully fluted wood Augers

Injecting into Side Slots (Type D and Type F) - 1 litre Skeleton Gun

Bonding Bars into timbers on site - for Solid Resin Repairs, Type A and Type B and TRS Timber Kits Type E and Type F - 400cc Skeleton Gun

Manufacturing Time for Timber Resin Splice Bressumer Repair Kits - minimum

Made in standard Kiln Dried Softwood (Pine) - 3 working days, plus 2 working days for delivery

Made in non standard Kiln Dried Softwood (Southern Yellow Pine, Douglas Fir) - 5 working days, plus 2 working days for delivery

Made in non standard Kiln Dried Hardwood (Oak) - 7 working days, plus 2 working days for delivery

Made in non standard Air Dried Hardwood (Oak) - 21 working days, plus 2 working days for delivery

Elm is also available to Special Order - expensive.

Drawings of installation steps for Timber Resin Splice Bressumer Repair Kits

Type A - Solid Epoxy Resin - removable shuttering - drilling up the end grain of the Parent timber on Site

Type B - Solid Epoxy Resin - permanent shuttering - drilling up the end grain of the Parent Timber on Site

Type C - Timber Resin Splice supplied with fitted bars - Top Slot(s) in the Parent timber.

Type D - Timber Resin Splice supplied with fitted bars - Side Slot(s) in the Parent timber

Type E - Timber Resin Splice supplied with Top Slot(s) - drill holes up the end grain of the Parent timber.

Type F - Timber Resin Splice supplied with Side Slot(s) - drill holes up the end grain of the Parent timber.

Type G - Timber Resin Splice supplied with Top Slot(s) - cut Top Slot(s) in the Parent timber.

Type H - Timber Resin Splice supplied with Side Slot(s) - cut Side Slot(s) in the Parent timber.

Method Statements for Timber Resin Splice Bressumer Repair Kits

Type A - Solid Epoxy Resin - removable shuttering - drilling up the end grain of the Parent timber on Site

Type B - Solid Epoxy Resin - permanent shuttering - drilling up the end grain of the Parent Timber on Site

Type A and B Modified - Solid Epoxy Resin - side slots in the Parent Timber due to lack of cutoff space to end drill

Type C - Timber Resin Splice supplied with fitted bars - Top Slot(s) in the Parent timber.

Type D - Timber Resin Splice supplied with fitted bars - Side Slot(s) in the Parent timber

Type E - Timber Resin Splice supplied with Top Slot(s) - drill holes up the end grain of the Parent timber.

Type F - Timber Resin Splice supplied with Side Slot(s) - drill holes up the end grain of the Parent timber.

Type G - Timber Resin Splice supplied with Top Slot(s) - cut Top Slot(s) in the Parent timber.

Type H - Timber Resin Splice supplied with Side Slot(s) - cut Side Slot(s) in the Parent timber.

Download Data Sheets and Safety Data Sheets for Resins

Structural Epoxy Pouring Resin and Grout - for pouring into slots and into cartridge tubes for injection - Data Sheet - Safety Data - Activator

Safety Data - Base - Safety Data - Powder

Thixotropic Epoxy Injection Resin - for injecting holes using 400cc cartridge tubes - Data Sheet - Safety Data Sheet Activator - Safety Data Sheet Base

Mouldable Epoxy Putty - for filling defects - Data Sheet - Safety Data Sheet

Where to find more reading and photographs of Timber Resin Repairs

www.timber-repair.co.uk - how to repair timber beams

Timber Repair Review 1 - Timber Repair Review 2 - call us for the printed versions - 01626 872886

TRADA Eurocode - resin repair technical report by the Timber Research and Development Association

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

Timber Decay Links for photographs of rots and insect damage

www.dryrot.biz - how to kill Dry Rot in buildings

www.woodworm-info.co.uk - how to kill and prevent woodworm and death watch beetle

www.woodworm-expert-advice-forum.org.uk - all your questions and our answers about woodworm damage and treatment

Technical Help for repairing Bressumer Beams

Property Repair Systems expert staff can help you with all kinds of timber repairs and are more than happy to give further information and advice.

Call 01626 872886 or E: Mail us help@propertyrepairsystems.co.uk

Timber Beam Repairs | Contact | About Us | About the Author | Index Page

Property Repair Systems

T: 01626 872886

E: Mail us help@propertyrepairsystems.co.uk

Site written by: David Moore

David Moore, B.A. (Hons.), C.T.I.S., C.R.D.S. Technical Author

Google+

Other Property Repair Systems Sites:

www.boron.org.uk - how to use Boron based insecticides/fungicides to treat timber rots and insect attack

www.dampness-info.co.uk - how to treat penetrating dampness in walls and plaster

www.deck-treatment.co.uk - how to treat patio decks and yacht decks

www.dryrot.biz - how to kill Dry Rot in buildings

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.fire-door-paint.co.uk - upgrade doors to 30 minutes fire resistance

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.propertyrepairsystems.co.uk - our Home Site

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber-repair.co.uk - how to repair timber beams

www.woodworm-info.co.uk - how to kill and prevent woodworm and death watch beetle

www.woodworm-expert-advice-forum.org.uk - all your questions and our answers about woodworm treatment DIY