Why repair cracks in wood

Cracks in timber beams need not affect the overall integrity of the structure. Indeed, cracks in timber beams can be taken as a positive visual feature of the timber, which, in conjunction with the timber grain, distinguish timber from the more uniform man-made materials such as steel and concrete.

- To improve fire resistance

- To improve resistance to weathering

- To improve mechanical performance

- To prevent wood rot and insect attack

In spite of this, there is a steady demand amongst specifiers for crack-injection of beams for the following reasons:

Repair Methods

Cracks, shakes, warps and fissures are formed as a result of the timber giving up moisture and shrinking. This may occur as part of initial drying or subsequent changes, during service, in the Equilibrium Moisture Content. The EMC of timbers inside buildings can range from 9% to 14%. Fibre saturation is reached in constructional softwoods at about 28%.

For cracks and splits that are greater than 5mm wide the void can be filled with our Mouldable Epoxy Putty, but if the crack penetrates more than 30% through the timber it will be necessary to provide dowels across the filled section in order to 'stitch' the two halves together. The advice of a Structural Engineer should be taken with regards to the number, diameter, length and spacing of the dowels. The dowels can be made of glassfibre, carbonfibre, steel or stainless steel. We normally recommend the use of epoxy/glass or epoxy coated steel, set in our epoxy adhesive, Thixotropic Epoxy Injection Resin.

|

|

Step 1 - clean out cracks with a saw blade and vacuum clean. Fill cracks with Mouldable Epoxy Putty, using our Epoxy Primer for hardwoods.

|

|

Step 2 - drill holes across the filled crack into sound timber on the opposite side. Blow out or vacuum out the wood dust.

|

|

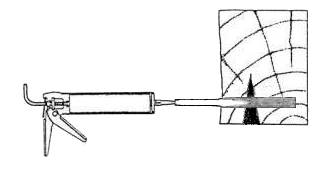

Step 3 - inject Thixotropic Epoxy Injection Resin from the hole base outwards using an extension tube.

|

|

Step 4 - fit dowels (into the Thixotropic Epoxy Injection Resin) at 100-150mm intervals, to act as connectors. Cap off holes with Mouldable Epoxy Putty

Timber Beam Repairs | About Us | About the Author | Index Page

Property Repair Systems

T: 01626 872886

E: Mail us help@propertyrepairsystems.co.uk

Site written by: David Moore

David Moore, B.A. (Hons.), C.T.I.S., C.R.D.S. Technical Author

Google+

Other Property Repair Systems Sites:

www.boron.org.uk - how to use Boron based insecticides/fungicides to treat timber rots and insect attack

www.dampness-info.co.uk - how to treat penetrating dampness in walls and plaster

www.deck-treatment.co.uk - how to treat patio decks and yacht decks

www.dryrot.biz - how to kill Dry Rot in buildings

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.fire-door-paint.co.uk - upgrade doors to 30 minutes fire resistance

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.propertyrepairsystems.co.uk - our Home Site

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber-repair.co.uk - how to repair timber beams

www.woodworm-info.co.uk - how to kill and prevent woodworm and death watch beetle

www.woodworm-expert-advice-forum.org.uk - all your questions and our answers about woodworm treatment DIY