Beam Upgrading

Upgrading a timber beam or floor requires an improvement in:

- Its ability to sustain a safe working load

- Its ability to resist deflection in bend

Our methods use a Structural Epoxy Pouring Resin to act as the method of transferring the load between timber and steel, rather than the traditional method, which uses a flat steel plate in a slot, known as a 'Flitch Plate' secured with bolts and nuts. In a traditional 'flitch' the bolts transfer the load - this is far less satisfactory than the uniform contact provide by epoxy resin.

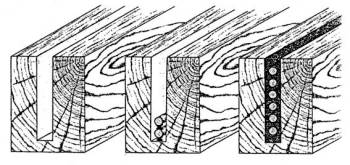

For ease of installation the ultimate in modified flitch design is the use of standard reinforcing steel bars (high tensile 'rebar') individually placed on spacers into the slot, surrounded by and bonded to the timber with Structural Epoxy Pouring Resin.

The advantage of this design is the greatly reduced weight of individual bars and ease of handling compared with a solid steel flitch plate (on a typical 6 metre span a flitch plate could weigh 300 kgs). The slot can also be cut to far lower tolerances, because the resin will take out all the gaps. There are no issues with drilling large holes through steel and no need for mechanical handling lifts (block and tackle) to lift the Flitch Plate - always a problem with solid steel.

Step by Step - to upgrade a timber beam

-

Decide the method of cutting and prepare the slot - Auger stitching, Chainsaw, Circular Saw, Router

-

Place the bars, using spacers (nuts or pieces of bar) at suitable intervals along the length of the cut and between each bar, maintaining a gap of 5mm to 10mm between the bars.

-

Mix and pour the Structural Epoxy Pouring Resin.

-

This should be carried out progressively from one end of the slot and until the slot is full.

Check out the photo gallery to view more pictures of a real job.

Structural Calculations for Upgrading Strength in Timber Beams

Free of charge - our Design and a Check Calculation - not Insurance Indemnified - we are not Structural Engineers - same day service

Chargeable - independent Structural Engineer - ask for one of our Forms - Indemnified by a Qualified Structural Engineer - allow at least 5 working days.

Carrier Beam Structural Data Collection Form - click here for the Form used when we submit your Beam Repair to a Structural engineer.

Epoxy Resins for Beam Strength Upgrades

To buy resins - visit our Resins Shop

Sealing beam defects: splits, cracks, insect holes etc. to avoid resin leakage - Quick Setting Wood Filler

Pouring into Top Slots - Structural Epoxy Pouring Grout

Injecting into Side Slots - Structural Epoxy Pouring Resin plus 1 litre Cartridges and Skeleton Gun

Bars used for Repairing Bressumer Beams

Bars fitted on Site - either Zinc Plated High Tensile Grade 8.8 Steel Allthread or locally obtained grit blasted High Tensile Rebar

Couplers - available for joining threaded bars and rebars in some applications

Technical Help

Property Repair Systems expert staff can help you with all kinds of timber repairs and are more than happy to give further information and advice.

Call 01626 872886 or E: Mail us help@propertyrepairsystems.co.uk

Property Repair Systems

T: 01626 872886

E: Mail us help@propertyrepairsystems.co.uk

Site written by: David Moore

David Moore, B.A. (Hons.), C.T.I.S., C.R.D.S. Technical Author

Google+

Other Property Repair Systems Sites:

www.boron.org.uk - how to use Boron based insecticides/fungicides to treat timber rots and insect attack

www.dampness-info.co.uk - how to treat penetrating dampness in walls and plaster

www.deck-treatment.co.uk - how to treat patio decks and yacht decks

www.dryrot.biz - how to kill Dry Rot in buildings

www.drywallandfloor.co.uk - membranes for lining damp walls, floors, basements and cellars

www.fire-door-paint.co.uk - upgrade doors to 30 minutes fire resistance

www.joist-repair.co.uk - how to quickly repair joists and beams of any size

www.propertyrepairsystems.co.uk - our Home Site

www.steel-fire-paint.co.uk - treat steel with Intumescent Paint to provide fire protection

www.timber-repair.co.uk - how to repair timber beams

www.woodworm-info.co.uk - how to kill and prevent woodworm and death watch beetle

www.woodworm-expert-advice-forum.org.uk - all your questions and our answers about woodworm treatment DIY